|

We are currently developing

this site. For more information regarding our services, please

contact us. |

|

|

The

AIRSŪSYSTEM, which

was showcased in Global Entrepolis Singapore 2003,

is an air cycle refrigeration system that uses

atmospheric air as a refrigeration medium. Although

air cycle machines have been known for a long time

and are used most typically on aircrafts, the high

costs involved in the technology have prevented its

widespread use in other industries.

However, the

AIRSŪSYSTEM has been developed with the aim of

increasing the reliability and effectiveness of the

air cycle technology with increased

cost-effectiveness. |

|

|

CFC & ammonia-free |

|

No CO2 emission |

|

|

Safe; Zero Risk of environmental hazards &

contamination of refrigerated goods |

|

|

No extra safety precautions or regulatory measures

needed |

|

|

Replenishment of refrigerant unnecessary as air is

used |

|

|

Defrosting unnecessary in warehouses |

|

|

The

AIRSŪSYSTEM is a

state-of-the-art air cycle refrigeration system

which completely does away with ammonia and CFC,

therefore eliminating the damage to the ozone

layer. As compared to CFC substitutes such as HCFC,

it has zero Global Warming Potential (GWP).

Therefore, with AIRSŪ system, you can be

environmental-friendly without compromising the

power of modern technology!

The

technology utilizes the cleanest and most natural

refrigerant, namely, air, as the cooling agent. Using a

2-stage compressor / heat-radiation and expander, the

resulting air temperature can be reduced to as low as –50°C.

Since the technology uses air as a refrigerant, no

additional costs are required in replenishing, as air is

freely available. Additionally, the

AIRSŪSYSTEM is composed of only a few but highly advanced

components, thus reducing installation time and maintenance

costs. |

|

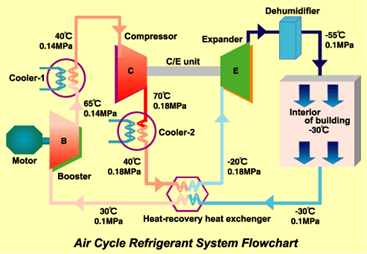

The

AIRSŪSYSTEM

produces very low temperatures efficiently using a

patented technology. Air is initially sucked in from

the refrigerated room by the booster compressor.

Heat is removed from the air via the heat exchanger

prior to entry into the expander turbine. The

booster compressor raises the pressure and the air

is cooled before entering the second compressor

which increases the pressure and temperature

further. |

|

|

The heat-exchanger is

then used to lower the temperature accompanied by

increased pressure; having further cooled in the

heat-exchanger; the air then gets expanded in the

turbine to a very low temperature. Lastly,

condensation is removed before the air is injected

into the refrigeration facility.

(See flowchart

above.)

This system has many applications in

various industries, including major applications in

refrigerated warehouses, delivery centers for groceries,

ship containers, shock freezing of foodstuff,

pharmaceuticals production, refrigerated show-cases,

air-conditioning systems, and others. |

|

|

|

Refrigerated warehouses

Refrigerated warehouses

Delivery Centres

Delivery Centres

Ship Containers

Ship Containers

Shock-freezing

Shock-freezing

Pharmaceutical Production

Pharmaceutical Production

Refrigerated show-cases

Refrigerated show-cases

Air-conditioning systems

Air-conditioning systems |

|